What’s a Centrifugal Pump?

Centrifugal pumps are mechanical devices designed to move fluids by converting mechanical energy into kinetic energy. These pumps have several components which all have a key role in achieving this operation.

What’s an Impeller?

The impeller is what some would consider the heart of any centrifugal pump, as it is responsible for accelerating fluid outward from the center of rotation. This is what allows the pump to generate enough pressure to drive the fluid through the discharge point. Therefore, when deciding against enclosed vs open impeller options, it is crucial you choose the enclosed impeller, which offers superior performance in even the most demanding conditions.

What Makes Enclosed Impellers Superior?

One of the core reasons why enclosed impellers are superior is because they utilize two shrouds, one on the top and bottom, resulting in a much stronger structure. The purpose of the shroud is to direct water gradually from the eye of the impeller, through vane passages to the impeller tip. Since both shrouds are connected to the enclosed impeller, they move with it as it spins, which helps minimize the wear rates.

Conversely, since the open impeller our competitors use does not have shrouds, stationary wear plates are used in their place which do not rotate with the impeller. As a result, enclosed impellers can provide the same level of performance as an open impeller, with a lower velocity relative to the spinning impeller vanes and shrouds, creating a much higher efficiency rating.

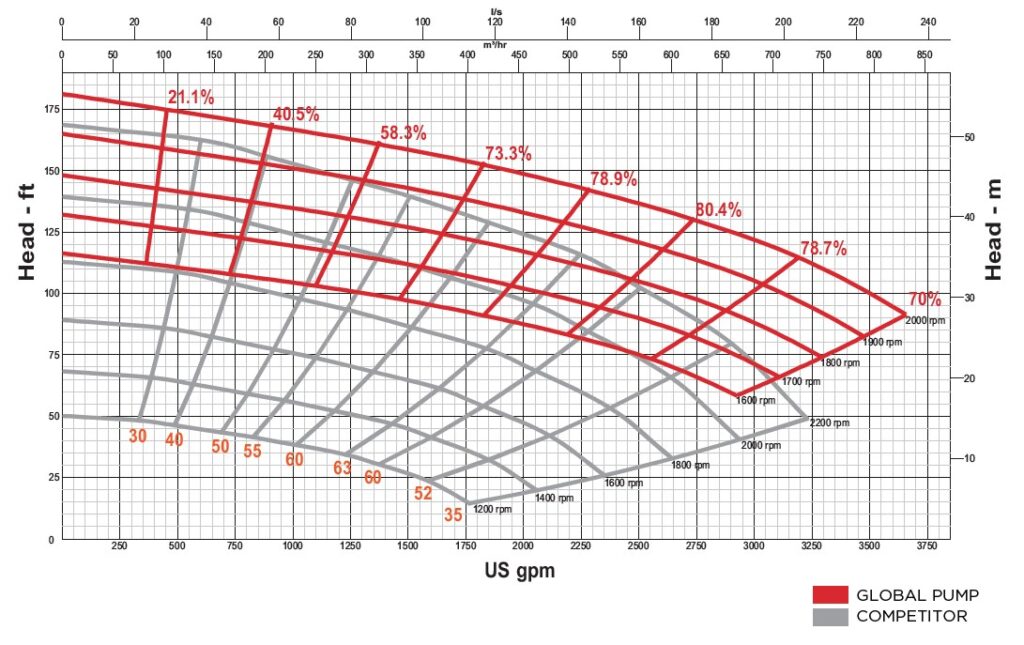

For instance, the example above compares the efficiency of an 8” Global Pump using an enclosed impeller and an 8” competitor pump using an open impeller.

Overall, choosing our pumps with enclosed impellers over those of our competitors will lead to

- Efficiency ratings up to 40% higher than our competition

- Lower engine power requirements

- Improved fuel consumption

- Less wear and tear

- Reduced maintenance and service times

- Longer run time per unit of fuel